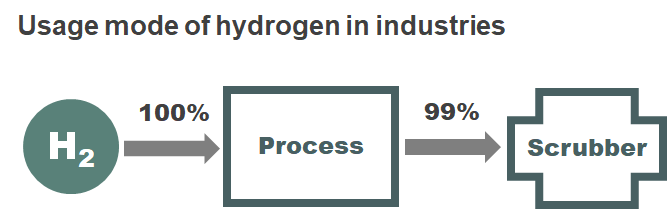

In many industrial processes, hydrogen is used as a protective gas with less than 1% consumed in the reaction, while 99% is discharged with mix of other gases which eventually vent to scrubber for either combustion or dilution.

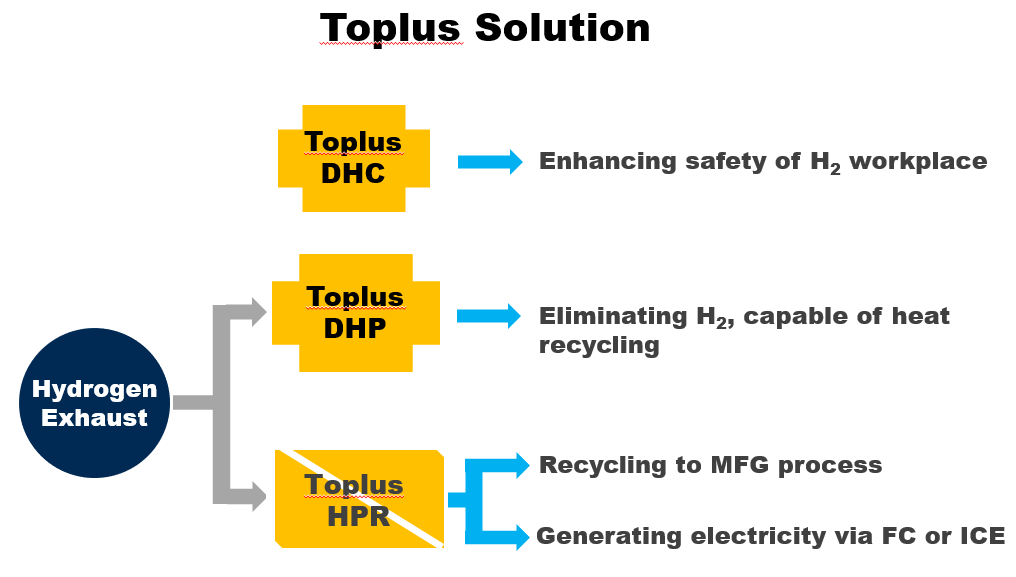

Toplus develops and manufactures innovative hydrogen purification and recycling (HPR) equipment which is the world’s first HPR equipment having SEMI S2 certification. With Toplus’ HPR, the discharged hydrogen can be purified in a safe way with high efficiency. The purified hydrogen can be recycled to the original process, helping to save hydrogen purchasing costs and energy consumption, or be used for power generation, all of which contribute to reduction of carbon emissions.

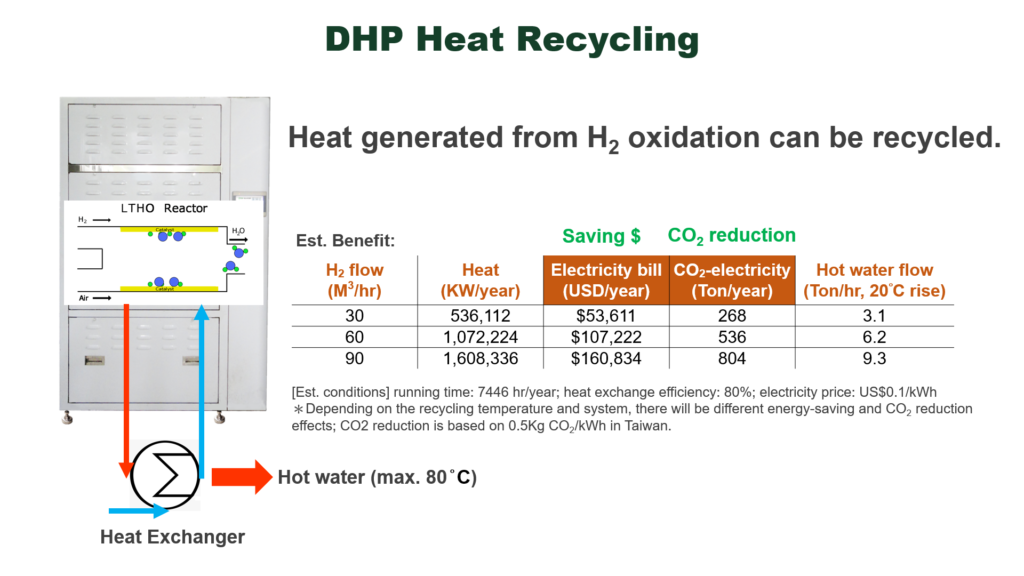

In response to the discharged hydrogen without recycling benefits, Toplus’ DHP pumping type dehydrogenizer, which is based on self-developed low-temperature hydrogen oxidation (LTHO) technology, eliminates hydrogen in an eco-friendly method with low energy consumption and zero emissions by converting hydrogen into water, moreover the heat energy arising from the process can be recycled.

Concerning the safety of indoor hydrogen leaks, Toplus’ DHC convection type dehydrogenizer adopts LTHO technology to convert the leaked hydrogen into water, avoiding hydrogen accumulation, thus improve safety of workplace.

Burning H2 is prone to generate NOx.

H2 emission is harmful to environment.

DHC enhances the safety of hydrogen workplace by preventing hydrogen accumulation in a confined space.

Hydrogen, the lightest gas, is prone to leak through the smallest gap and should not be allowed to collect in confined spaces or poorly ventilated areas. Toplus DHC is a convection type dehydrogenizer which can eliminate hydrogen leaks by converting H2 into H2O to avoid hydrogen accumulation, it works out of the box without power required.

Toplus ECHP purifies hydrogen exhaust by sperating nitrogen with safe and high efficiency.

Many hydrogen exhaust gases contain nitrogen which is not easy for speration when performing purification.

Toplus Electrochemical Hydrogen Purifier (ECHP) is designed to purify hydrogen exhaust by separating nitrogen gas under ambient pressure and low temperature, the recycling efficieny can be up to 80%.

For hydrogen to be a net-zero solution, emission should be tackled eco-friendly.

Hydrogen in air is flammable over the range of four to seventy-five percent concentration, vented hydrogen is traditionally treated by either combustion or dilution, but both methods are not ideal eco-friendly. Based on Low Temperature Hydrogen Oxidation (LTHO) technology, Toplus’ DHP series pumping type dehydrogenizer is designed to eliminate hydrogen in safe, zero CO2/NOx emission, low energy consumption and capable of heat recycling. The product allows hydrogen to be converted into water by mixing hydrogen with oxygen of air and then passing through the catalyst reactor to ensure residual hydrogen concentration lower than 4000ppm. Reaction takes place at temperature lower than 100 degree Celsius and ensures that a flame cannot occur.

Besides the traditional combustion or dilution, you have better way to treat vented hydrogen.

Toplus DHP pumping type dehydrogenizer provides an ambient-temperature, zero-emission, energy-saving and eco-friendly solution of hydrogen elimination.

The heat generated from hydrogen oxidation can be recycled, it can help you to save electricity bills and reduce carbon emissions.