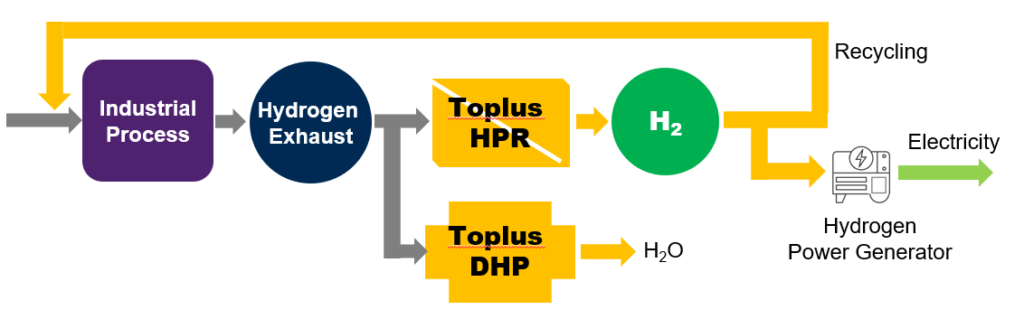

Toplus’ solution on the treatment of hydrogen exhaust

Toplus’ hydrogen purification and recycling (HPR) solution is designed to purify hydrogen exhaust in industrial process which traditionally is discarded due to limitation of legacy technology. The purified hydrogen can be recycled to the process, or being used for power generation.

The HPR solution includes two types of equipment: Electrochemical Hydrogen Purifier (ECHP) and Porous Ceramics Adsorbent Purifier (PCAP); both of which can work under normal pressure without the need to compress hydrogen.

The ECHP is used to remove N2, while PCAP is used to remove substances other than N2, such as H2O, O2, NH3, VOCs,… etc. Depending on the composition of exhaust gases and requirement, they can be used alone or in combination.

In the cases that exhaust hydrogen needs to be discarded, legacy treatments may not be ideal eco-friendly and safe. Toplus develops and manufactures innovative dehydrogenizer product line based on low temperature hydrogen oxidation (LTHO) technology, it adopts a flameless and safe operation by converting H2 into H2O, and the residual hydrogen concentration can be lower than 4000ppm (10% LEL).

The LTHO product line contains two series of dehydrogenizers including DHC convection type and DHP pumping type.

DHC is used to eliminate leaked hydrogen in a confined space. It can avoid hydrogen accumulation in poorly ventilated area, so as to enhance safety.

DHP is used to eliminate the exhaust hydrogen from pipeline, normally it deals with larger amount and higer concentration of hydrogen. It allows the hydrogen to be oxidized to a safe level concentration before being discharged, and if required the heat energy arising from the oxidation process can be recycled.