Benefits

- Enhance Safety: real-time elimination of H2 leaks to avoid accumulation

- Reduce risk of devices failure: H2 accumulation may arise from ventilation or sensor failure, power outage, emergency response,..etc.

- Simple installation and zero maintenance cost: just mount on the ceiling and work, no power required, no consumables, no fuel required

- Enhance public confidence on H2

- Eco-friendly: Convert H2 into H2O

- Increase safety factor for insurance

- UL witness inspection

Toplus DHC Series works without electricity. It uses catalysts to oxidize hydrogen by the oxygen in the air at room temperature. The reaction will generate heat to increase reaction efficiency and cause air convection. The DHC Series can eliminate the accumulated hydrogen gas arising from poor ventilation or devices failure, and improve safety. It is suitable for all workplaces where hydrogen leaks may occur, including hydrogen-related laboratories, hydrogen fuel cell rooms, hydrogen cylinder rooms, lead-acid battery charging rooms, fuel cell vehicles and garages, water electrolyzer rooms, metal heat treatment factories, hydrogen refueling stations, hydrogen power plants, and hydrogenation processing plants of food, beverage and pharmaceuticals.

Specifications

| Model | Max. treatment of H2 leaks | Dimension-mm (excluding fixtures) | Weight (kg) |

| DHCVZ2B | 2 LPH | 121×46±10 (diameter x height) | 0.27±0.05 |

| DHCV10A | 10 LPH | 181.5×101.5±10 (diameter x height) | 0.65±0.05 |

Usage Example

Hydrogen is much less dense than air, it can diffuse rapidly and accumulate in the top of the confined space (as left-side video), so DHCs are typically installed on top of possible leaked points and poorly ventilated areas (as right-side video).

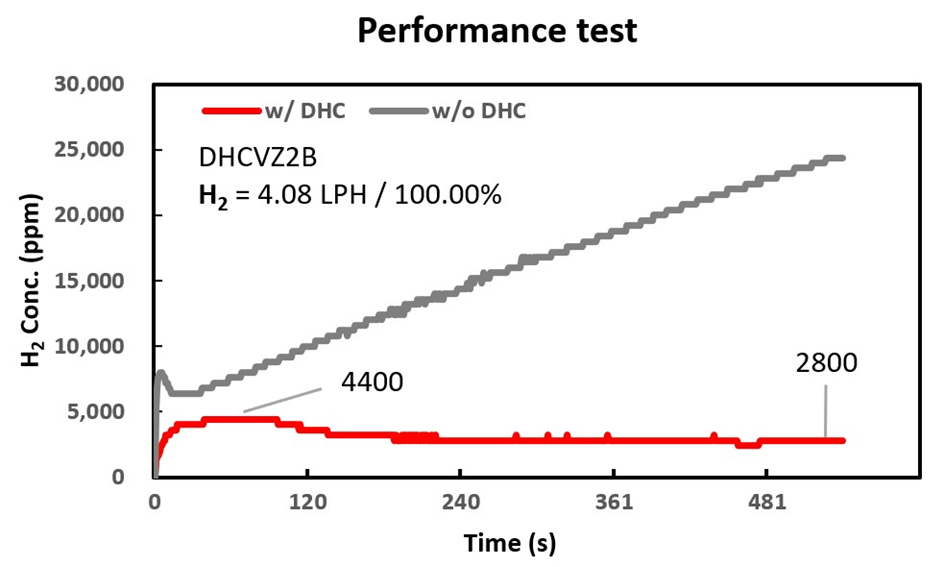

Performance Test

The test is done by continuously injetting a fixed flow rate of hydrogen in a confined space, the black curve is measured without DHC, while the red curve is measured with DHC which indicates that the hydrogen concentration is declined to a safe level.